By Solomon Crenshaw Jr.

For The Birmingham Times

Bobana Harris has always been a fan of robots.

“I liked building things,” said the 23-year-old of Montevallo. “That’s what pushed me toward robotics and electronics. It’s a really neat program that allows you to work with robots and program them.”

Harris is majoring in industrial electronics at Lawson State Community College with an eye toward becoming an electrician or entering the manufacturing field.

On a recent November afternoon, Harris and classmates had just completed a test that involved a computer simulation.

“We’re practically making models on the computer and comparing them to the real robots,” Harris explained. “There’s different types of programming you can do. You learn how to program it, run it from start to finish.”

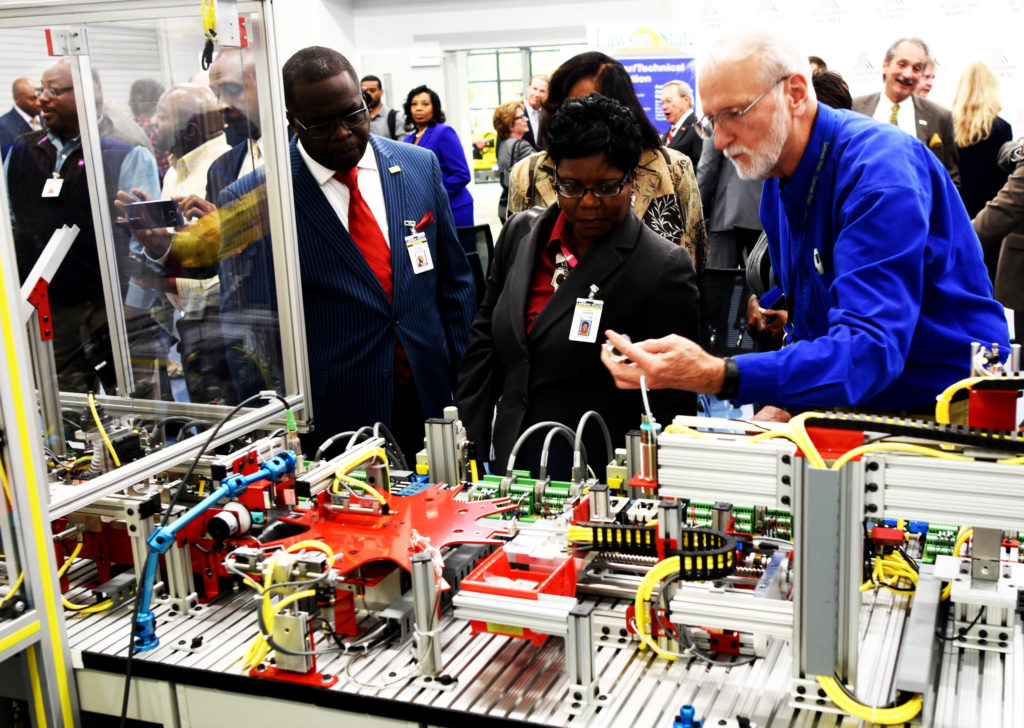

Between its Birmingham and Bessemer campuses, Lawson State has nearly $1 million in equipment to prepare students for a wide range of jobs. The two-year college has several different trade programs, as well as one of the nation’s most renowned automated manufacturing multidiscipline programs, which includes robotics, electrical, machine tool, industrial electronics, automated manufacturing, and industrial maintenance.

“We’re trying to make sure our students are trained for the workforce,” said Bruce Crawford, Lawson State’s vice president for instructional services. “They can actually replicate things that they learn here in the industry. They can troubleshoot, all that kind of stuff.”

Preparing for the Workforce

On Nov. 15, 2016, at Lawson State, the Alabama Workforce Council unveiled AlabamaWorks!—a system that links employers with Alabamians seeking jobs or job training. It’s no coincidence that the event was held at the school’s Bessemer campus. Lawson State has gained a reputation for programs that prepare students for the future.

Ed Castile, deputy secretary of the Department of Commerce, was among those on hand at the unveiling.

“The good news is that students are growing up with technology none of us had,” said Castile, who is also executive director of Alabama Industrial Development and Training (AIDT). “As tots, they grow up with technology. Even pre-K is developing a workforce at some point. That kid’s going to wind up in a job somewhere, and who knows what that kid’s job is going to look like? But they’re certainly going to have a lot of technology, and the digital world will be far advanced from what it is now.”

Crawford pointed out that Lawson State is closely aligned with preparing students for careers in technology.

“Robotics is one of the areas we’ve been focusing on lately,” he said. “We’ve been focusing on the industrial electronic areas, as well.”

At Lawson State, students learn what it takes to plan a career in robotics, Crawford said.

“We have support from the National Science Foundation to train high school students in the summertime in science, technology, engineering, and mathematics [STEM],” he said. “Also, during the school year we have regularly enrolled students who serve as STEM scholars. They do research activities, and many of them work with major in-state and out-of-state universities in the summertime. One young lady even went to Africa to do research.”

Lawson State has a lot more robots than most other places because the school uses a variety of brands to expand the student experience, said Nancy Wilson, assistant dean of career technical education and chair of the manufacturing and engineering division.

New Ways of Doing Things

Lawson State is a perfect fit for students of any age who are interested in preparing for the ever-evolving workforce.

Robotics student Cedric Brundidge, 59, is doing his second stint at Lawson’s Bessemer campus. The school was named Bessemer Tech when the McCalla resident earned an electronics degree in 1989 before going to work at U.S. Steel.

“The plant shut down,” he said, “and I’ve got another 15 or 20 years of work left in me, hopefully. I’d like to get on with a tier-one company, fabricating parts and making parts for the auto manufacturers here in Alabama.”

Fifty-four-year-old Vincent Banks of Pleasant Grove tells a similar story. He, too, was laid off from U.S. Steel’s Fairfield Works. He’s at Lawson State with plans to get into automation manufacturing.

“As time goes by, you get new technology, new equipment, new ways of doing things,” he said. “It’s more robot-animated now. Automation is the key for manufacturing.”